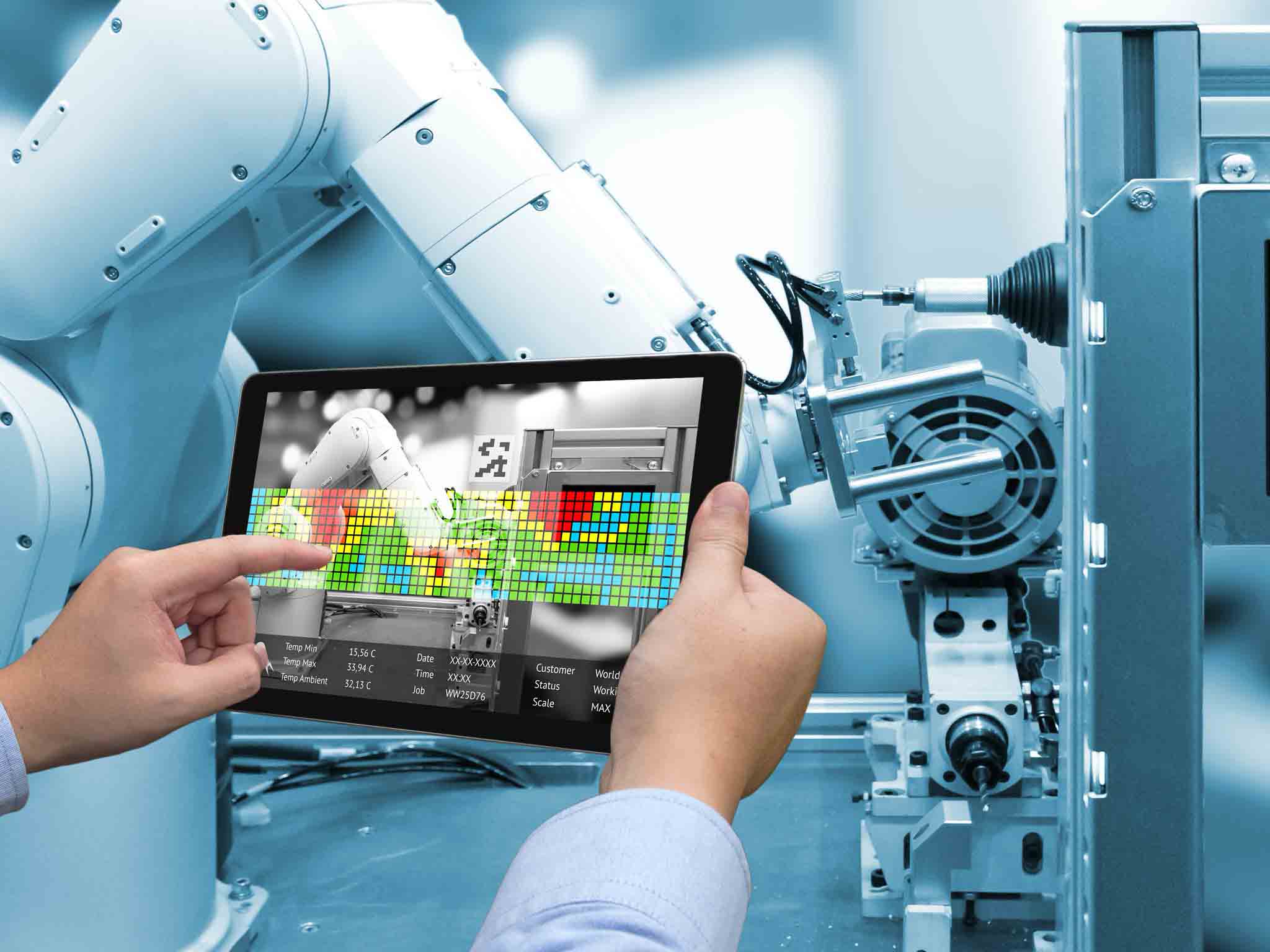

Industry 4.0 is about the automation and exchange of data in manufacturing technologies. It includes cyber-physical systems, the Internet of things, cloud computing and cognitive computing.

We use data analytics and robotics process automation in enabling Industry 4.0 technology to your company. Predictive & proactive maintenance, early warning detection, planning, risk management, customer experience and automation of repetitive & standardized tasks helps you to stay ahead of the game. This helps in establishing a proactive culture besides reducing costs & improving profitability and enhancing customer & employee loyalty.

PPM can used to

maximize the uptime of critical equipments.

The current maintenance model is not predictive and is predominantly time based as per OEM manual. But time based preventive maintenance is costly because it leads to unplanned repairs and downtime of machines. Our solution predicts anomalies and estimates residual life of critical equipment to optimize timing for intervention.

Prediction of low frequency high

impact failures (equipment such as compressors).

Anti-surge control systems and high/low limits on surges are unable to prevent failure on their own.

We use machine learning to provide earlier detection of failures and assist engineer in diagnostic processes. Along with prediction, we can also build a system for engineers to get alerts.

Predict issues on

the equipment that is monitored manually

A typical example for this would be fouling on heat exchangers. This recurring issue can cause unexpected failures on other assets.

Preventive maintenance is difficult to plan and execute as individual performance may not be tracked.

Machine learning algorithm on the other hand can predict heat exchanger performance on a regular basis based on past data.

Model can send alerts when the performance degrades beyond a certain point.